Fiber Products

Rockwool – MG products

MG products (made of rock wool) are light and highly flexible, thus offering outstanding handling and workability. They also have high heat retention and insulation, and good sound absorption properties, and so are widely used in buildings and industrial equipment and apparatus.

| Product Code | Product Name | Description | Application | Industry |

|---|---|---|---|---|

| MG BOARD™ *080 *120 *150 *200 *080-ALGC, -GC |

MG BOARD™ | - Add a thermosetting resin to rock wool as a binder and molding it into a board - Excellent heat and thermal insulation and sound absorption properties. - Lightweight and flexible - Max Temp: Upto 600 °C |

- Heat insulation, thermal insulation, and noise dampening for steel plate ducts - Heat and thermal insulation for plant equipment and sound absorption for machine rooms and electrical rooms - Core material for partition walls and filler material for parts that pass through fire compartments - Sound-absorption materials such as for studios and halls Backup materials for ceramic fiber furnace materials - Filler materials for suspended, lightweight partition walls - Thermal insulation and soundproofing for air conditioning facility ducts and equipment - Thermal insulation and soundproofing for the ceilings, walls, partitions, and doors of buildings - Sound absorption of machine rooms and generator rooms - Acoustic sound-absorption materials such as for studios and halls |

- Energy (Electricity, Gas, Heat Supplies) |

| MG WIRED BLANKET™ 080 (Galvanized iron wire) | MG WIRED BLANKET™ | - Fix hexagonal wire mesh to one side of MG BOARD with iron wire and roll it up into a roll. - Excellent heat and thermal insulation and sound absorption properties. - Lightweight and flexible - Max Temp: Upto 600 °C |

Thermal insulation, soundproofing, and fire resistance for: - Boiler furnace walls, tanks, and smoke airways - Thermal power generation, various plant pipes, tanks, and towers - Large diameter pipes, ducts, and equipment of air conditioning facilities |

|

| MG MIGHTY ROLL™ *ALGC *ALK |

MG MIGHTY ROLL™ | - Resin are added to rock wool as a binder before molding it into a feltm then affix ALK (aluminum craft foil) or ALGC (aluminum glass cloth) to one side before rolling - Excellent heat and thermal insulation and sound absorption properties. - Lightweight and flexible - Max Temp: Upto 600 °C |

Heat and thermal insulation for: - Various ducts for air conditioning facilities - Various equipment - Various pipes and valves Fire protection material for kitchen exhaust ducts in housing complexes Thermal insulation, heat insulation, and condensation prevention for the ceilings, walls, and partitions, of buildings |

|

| *MG MIGHTY COVER *MG MIGHTY COVER ALGC |

MG MIGHTY COVER™ | - Excellent thermal insulation, heat resistance, and non-flammable properties - Max Temp: Upto 600 °C |

Heat and thermal insulation for: - Various pipes - Copper pipes Processing for parts that passes through fire compartments |

|

| MG BELT™ *070 *070-ALGC *120-ALGC |

MG BELT™ | - Cut MG BOARD into strips and reinforcing it with cheesecloth. - Excellent heat and thermal insulation and sound absorption properties. - Lightweight and flexible - Max Temp: Upto 600 °C |

- Heat insulation for air conditioning ducts, various pipes, and tanks - Fire protection material for kitchen exhaust ducts in housing complexes *Filling for fireproof and sound-damping wall partitions *Filling for general walls *Wall and ceiling insulation MG BUILDPACK - Add thermosetting resin to rock wool as a binder, mold it into a mat form, and then cover the six surfaces with polyethylene film. - Thermal insulation performance equivalent to that of a 24 K glass wool product. - Filler for wall partitions that require sound insulation performance such as in stores and mansions - Installed on the ceilings of plants and welfare facilities |

Alumina fiber

Alumina is an aluminum oxide, offering outstanding heat resistance, chemical resistance, and strength. It is crystallized and turned into a product by high-temperature treatment.

| Product Code | Product Name | Description | Application | Industry |

|---|---|---|---|---|

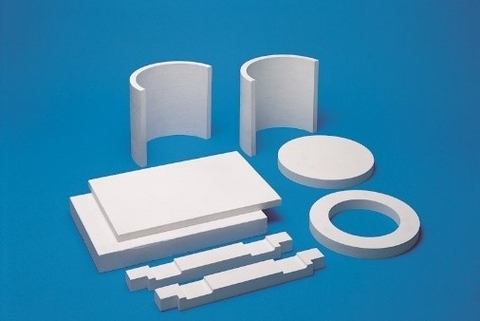

| Tombo No. 5461 | RF Board | - Add inorganic and organic binders to alumina fiber and then mold this into a board form. - Excellent workability - Lightweight and has low thermal conductivity excellent insulation performance - Chemically stable - Can be manufactured into a processed product or molded product. - Service temperatures ~ 1400°C to 1800°C |

Lining material for: - Electrical furnaces that rapidly rise and drop in temperature - Various high-temperature furnaces - Electrical component ovens |

- Energy (Electricity, Gas, Heat Supplies) - Thermal Power Stations (Coal) - Thermal Power Stations (LNG) - Nuclear Power Stations - Hydrogen and Ammonia - Biomass Power Generation and Heat Supply Plants - Electronics - Semiconductors & Flat Panel Displays (FPD) - Electronic Components - 5G - Batteries & Electricity Storage Systems - Carbon Neutrality and Decarbonization - Industrial-Use Insulation - Energy Saving Proposals - Hydrogen and Ammonia - Biomass Power Generation and Heat Supply Plants - Various Plant Facilities - Industrial Furnaces (Electric Furnaces/Combustion Furnaces) |

Fineflex BioTM

Made from amorphous fibres, alkaline earth silicate (=AES) products exhibit low thermal conductivity, low bio-persistence and low linear shrinkage. NICHIAS leveraged those advantages in products such as AES paper for general purpose insulation to AES cast used in heating furnaces. We call this product range - FINEFLEX BIO™.

| Product Code | Product Name | Description | Application | Industry |

|---|---|---|---|---|

| Tombo No. 5605 | FINEFLEX BIO™ Bulk | - Join together silica, magnesia, and calcia-based alkali earth silicate (AES) wool. - Excellent heat resistance - Low conductivity rate - Excellent thermal shock resistance - Lightweight and easy to handle - Maximum heat resistant temperature: 1300°C |

- Filler material for insulating the ceilings and walls of various kilns - Expansion filler material for the ceilings and walls of various kilns - Expansion joint packing material for various kilns |

- Energy (Electricity, Gas, Heat Supplies)

|

|

Tombo No. 5615 #100 Tombo No. 5615-LT |

FINEFLEX BIO™ Blanket | - Layer silica-magnesia-calcia-based alkaline earth silicate (AES) wool, mold it into a blanket shape, and then subject it to needle punching - Excellent heat resistance - Low conductivity rate - Excellent thermal shock resistance - Lightweight and easy to handle - Maximum heat resistant temperature: Tombo No. 5615 (1300°C), Tombo No. 5615-LT (1200°C) |

- General insulation - Insulation lining material and backup material for the ceilings of kilns and furnace walls - Expansion allowance filler for each part within a furnace |

|

|

Tombo No. 5625 -M/ -A |

FINEFLEX BIO™ Board | - Add inorganic and organic binders to FINEFLEX BIO Bulk and molded into a board form. - Lightweight, low thermal conductivity, excellent insulation performance - Maximum heat resistant temperature: 1300°C |

- General high-temperature insulation - Lining material and backup material for insulating the ceilings of kilns and furnace walls - Expansion allowance filler for each part within a furnace - Gas sealing materials |

|

|

Tombo No. 5635 -A/-R/-M |

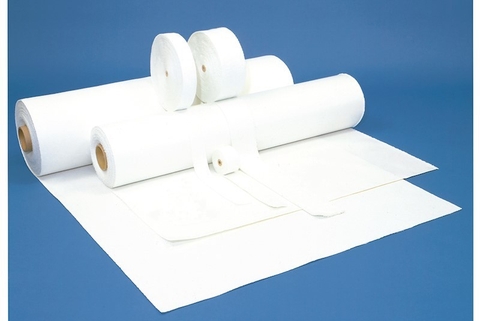

FINEFLEX BIO™ Paper | - Add a small number of organic binders to FINEFLEX BIO Bulk - Maximum heat resistant temperature: 1300°C |

- General insulation - Insulation lining material and backup material for the ceilings of kilns and furnace walls - Expansion allowance filler for each part within a furnace - Heat sealing material for gas supply equipment - Heat sealing material for combustors |

|

| Tombo No. 5645 | FINEFLEX BIO™ Mold | - Add inorganic and organic binders to FINEFLEX BIO Bulk and molded into various shapes by way of a suction molding method - Lightweight, low thermal conductivity, excellent insulation performance - Maximum heat resistant temperature: 1300°C |

- General high-temperature insulation - Insulation for the inside of compact electric furnaces - Aluminum tap hole and stopper cover - Other thermal and heat insulation materials and backup materials |

|

| Tombo No. 5655 -B/-S/-W |

FINE BLOCK™ | - Mold FINEFLEX BIO Blanket or an alumina fiber blanket into a block form. - Maximum heat resistant temperature: 1300°C ~ 1600°C |

- Industrial furnace and steel-related lining materials - Veneering materials |

|

| Tombo No. 5675 -400/-700/-400P |

FINEFLEX BIO™ CAST | - Wet-mix FINEFLEX BIO Bulk and inorganic binders, etc - Maximum heat resistant temperature: 1300°C |

- Heating furnace skid pipe host for steel - Casting heating furnace ceilings and side walls - Outer wall sealing for glass tank kiln chamber - Burner tiles and roller tiles - Repairing of existing heat resistance material |

|

|

Tombo No. 5685 -A/-B/-C/-D/-E |

FINEFLEX BIO™ Textile | - Cloths, tapes, cords, and ropes manufactured by mixing a small number of organic fibers with silica-magnesia-calcia-based alkali earth silicate (AES) wool - Excellent heat resistance - Low thermal conductivity - Excellent thermal shock resistance - Lightweight & easy to handle |

- Furnace heating zone separators and curtains, and covers for thermocouple lead wires - Sealing around furnace doors and burners |

Giỏ hàng

Giỏ hàng