Fluoroelastomer (Special FKM) Orings

TOMBO™ No. 2670-FA-F Rubber O-ring Fluoro-Plus (Special FKM)

TOMBO™ No. 2670-FA-F

Rubber O-ring Fluoro-Plus

Fluoro-Plus is a special fluoroelastomer (Special FKM) that maintains the chemical resistance and heat resistance of a regular fluoroelastomer but has significantly improved wear resistance and non-stickiness.

Fluoro-Plus is different from outer membrane coatings and is a product that undergoes treatment by way of a surface improvement method. As a result, it maintains its attributes over the long term and it experiences no peeling of the surface layer.

Features

Heat resistance guide*: 200°C

Standard hardness (Duro A): 70

It Its friction coefficient is about 1/2 of a standard fluoro elastomer.

Its adhesion with metal is about 1/5 of a standard fluoro elastomer.

It undergoes surface modifying processing and so there is no peeling of the surface layer.

Applications

Sealing of parts that continuously slide or move along a surface, parts that open and close repeatedly (sealing of various control valves), and parts that adhere strongly to metal and are difficult to maintain

Precautions for use

Fluoro-Plus is less adaptable to mating surfaces than Fluoroelastomer FA, so do not use it for applications that require a high vacuum seal.

Non-adhesive

Inspected by Nichias

Test method

Test sample: O-ring (JIS P 26)

Compression rate: 25%

Flange material: aluminum

Heating conditions: 200°C × 22 hrs

- TOMBO is a registered trademark or trademark of NICHIAS Corporation.

- Name of products with "®" are registered trademarks of NICHIAS Corporation.

- Name of products with "™" are trademarks of NICHIAS Corporation.

TOMBO™ No. 2675-FE BLAZER™ O-ring-FE (Special FKM)

TOMBO™ No. 2675-FE

Blazer O-ring-FE

BLAZER O-ring-FC (BFC) and BLAZER O-ring-FE (BFE) are made of special fluoroelastomers (special FKM) that are plasma resistant and inexpensive. Thanks to Nichias’ blending technologies, the plasma reduces the weight of the rubber and reduces the occurrence of cracks, and at the same time, it is significantly less expensive than perfluoroelastomer (FFKM).

Features

Heat resistance guide*: 200°C

Standard hardness (Duro A): 60

It is a material that is not susceptible to suffering a reduction in weight or cracks due to plasma exposure.

As it has excellent non-stickiness, it can also be used with movable parts without any problems.

It has a low metal content, thereby reducing any particle-related problems.

Applications

Can be used in semiconductor & LCD manufacturing equipment, the sealed parts that are exposed to the plasma environment (Sealing of plasma etching units)

Parts that have problems in terms of lifespan and particles with FKM.

Parts for which the cost and performance are too great with FFKM.

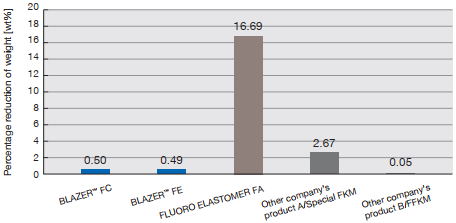

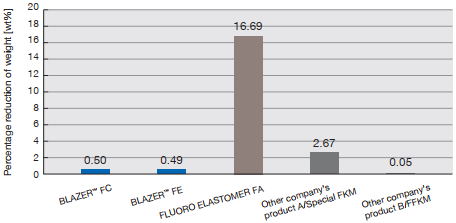

Plasma resistance (weight reduction rate)

Assessment conditions

Equipment: surface wave plasma etching equipment

Test sample shape: AS568B-214

Gas type: O2 (2000 SCCM) + CF4 (40 SCCM)

Pressure: 133 Pa

Output: 2000 W

Exposure duration: 2.0 hrs

Elongation rate: 5%

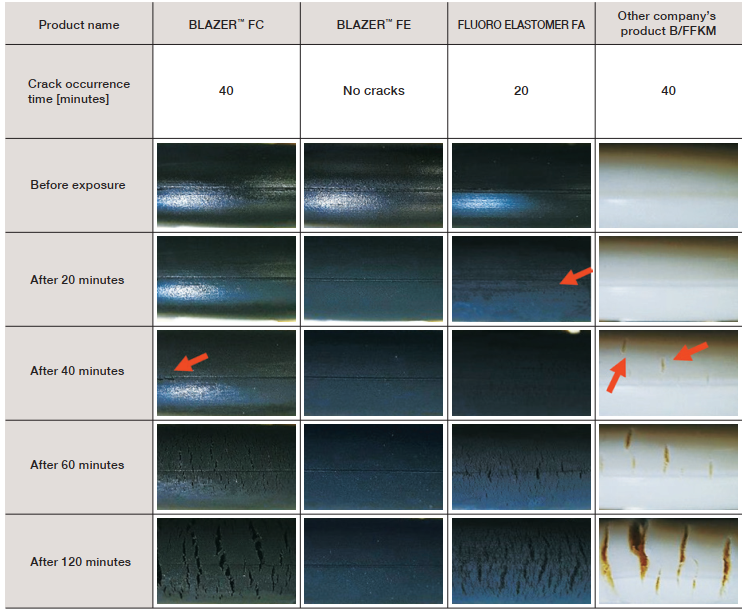

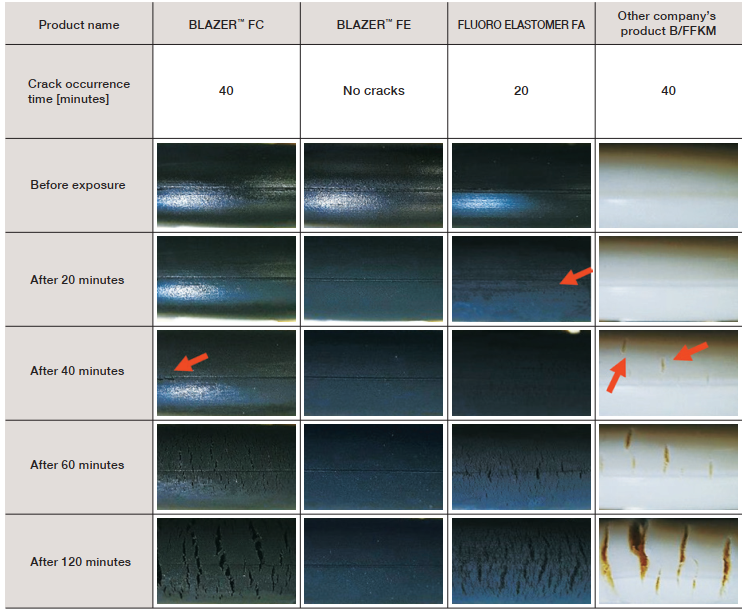

Plasma resistance (crack resistance)

Assessment conditions

Equipment: surface wave plasma etching equipment

Test sample shape: AS568B-214

Gas type: O2 (2000 SCCM) + CF4 (40 SCCM)

Pressure: 133 Pa

Output: 2000 W

Exposure duration: 2.0 hrs

Elongation rate: 5%

Appearance observation: up to 20 minutes with 5-minute intervals and then up to 120 minutes with 10-minute intervals

- TOMBO is a registered trademark or trademark of NICHIAS Corporation.

- Name of products with "®" are registered trademarks of NICHIAS Corporation.

- Name of products with "™" are trademarks of NICHIAS Corporation.

TOMBO™ No. 2675-FC BLAZER™ O-ring-FC (Special FKM)

TOMBO™ No. 2675-FC

Blazer O-ring-FC

BLAZER O-ring-FC (BFC) and BLAZER O-ring-FE (BFE) are made of special fluoroelastomers (special FKM) that are plasma resistant and inexpensive. Thanks to Nichias’ blending technologies, the plasma reduces the weight of the rubber and reduces the occurrence of cracks, and at the same time, it is significantly less expensive than perfluoroelastomer (FFKM).

Features

Heat resistance guide*: 200°C

Standard hardness (Duro A): 60

It is a material that is not susceptible to suffering a reduction in weight or cracks due to plasma exposure.

As it has excellent non-stickiness, it can also be used with movable parts without any problems.

It has a low metal content, thereby reducing any particle-related problems.

Applications

Can be used in semiconductor & LCD manufacturing equipment, the sealed parts that are exposed to the plasma environment

Parts that have problems in terms of lifespan and particles with FKM.

Parts for which the cost and performance are too great with FFKM.

Plasma resistance (weight reduction rate)

Assessment conditions

Equipment: surface wave plasma etching equipment

Test sample shape: AS568B-214

Gas type: O2 (2000 SCCM) + CF4 (40 SCCM)

Pressure: 133 Pa

Output: 2000 W

Exposure duration: 2.0 hrs

Elongation rate: 5%

Plasma resistance (crack resistance)

Assessment conditions

Equipment: surface wave plasma etching equipment

Test sample shape: AS568B-214

Gas type: O2 (2000 SCCM) + CF4 (40 SCCM)

Pressure: 133 Pa

Output: 2000 W

Exposure duration: 2.0 hrs

Elongation rate: 5%

Appearance observation: up to 20 minutes with 5-minute intervals and then up to 120 minutes with 10-minute intervals

- TOMBO is a registered trademark or trademark of NICHIAS Corporation.

- Name of products with "®" are registered trademarks of NICHIAS Corporation.

- Name of products with "™" are trademarks of NICHIAS Corporation.

Giỏ hàng

Giỏ hàng