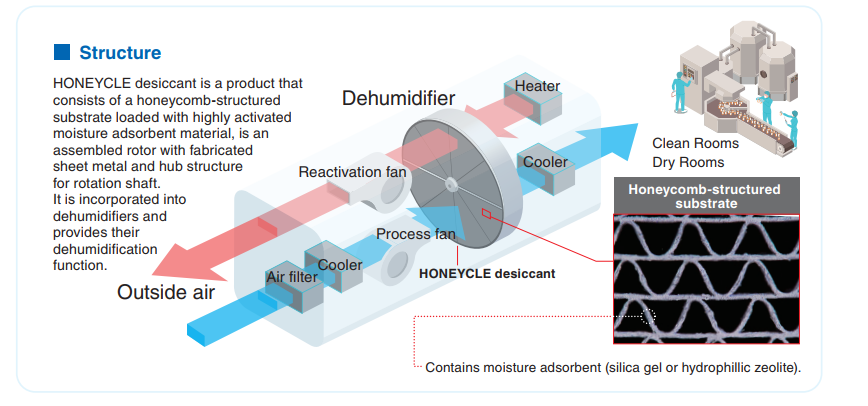

In recent years, humidity control has become indispensable in a variety of industrial fields, such as, pharmaceutical production, food process, chemical industry, semiconductor production process, and lithium-ion battery production, because of the quality problems that moisture in the air can cause. Dehumidification methods for controlling and managing moisture include desiccant dehumidification, which uses moisture adsorbents, and dehumidification by condensation, which reduces moisture under overcooled condition. We have been supplying the market with honeycomb rotors for dehumidification (hereinafter referred to as HONEYCLE desiccant) for many years.

STRUCTURE

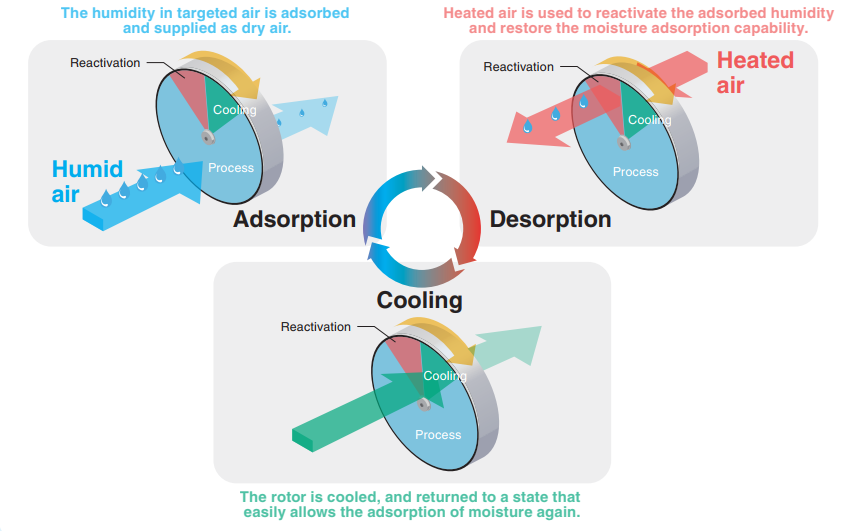

BASIC MECHANISM

HONEYCLE desiccant rotor is used in the devices with heat-resistant seals that are divided into either (A) a process zone and a reactivation zone, or (B) a process zone, a cooling zone, and a reactivation zone. Dehumidification (adsorption) and reactivation (desorption) are performed by rotation at the optimal speed as determined by the condition of the air, making it possible to supply a dry air continuously.

PRODUCT LINEUP

| AC-SG/EX-SG | MS-D | DH | |

| Application |

• Relatively high-humidity air conditions in lithium-ion battery plants, office buildings, chemicals, food, and pharmaceutical plants. • Suitable for semiconductor factory, Li-ion battery factory, and others for low dew point |

• Suitable for plastic-molding process (hopper dryers). • Drying for high temperature air. |

• Suitable for semiconductor factory, Li-ion battery factory, and others for low dew point. |

| Moisture adsorbent | Silica gel | Hydrophilic zeolite | Silica gel + Hydrophilic zeolite |

| Features | • High adsorption capacity, ideal for high humidity. • Low-temperature reactivation is possible. • Dehumidifying performance tends to decrease at higher temperatures. |

• Availables consistent adsorption in high temperature, low humidity air. • Low adsorption capacity, unsuitable for more humid air. • Performance hardly degrades even under circulated air conditions. |

• Dehumidification at ultra-low dew points is achieved using rotors in series (silica gel for the first stage and zeolite for the second stage). |

| Maximum reactivation temperature | 140 ̊C | 180 ̊C | 180 ̊C |

APPLICATION

|

|

|

|

|

| LiB production | Pharmaceutical production |

Data centers | Paint booth (automotive) |

Food process |

| Plastics | Clean Rooms | Dry Rooms | Office building air conditioning | School and hospital air conditioning |

| Supermarket air conditioning | Dehumidification of swimming pools and ice skating rinks |

Water damage by flooding Drying crawlspaces and lofts |

Dehumidifiers for event spaces and events |

Rust prevention for bridge piers and wind power generation Preventing rust on steel pylons |

You addred [ ] to cart

You addred [ ] to cart