Elastomer Products

TOMBO™ No. 2670-BNX Rubber O-ring BLAZER NEXT™ (FFKM)

TOMBO™ No. 2670-BNX Rubber O-ring BLAZER NEXT™

BLAZER NEXT is a perfluoroelastomer (FFKM) with excellent heat resistance, radical resistance, purity, and non-stickiness thanks to Nichias’ proprietary cross-linking technologies. It seals in strict environments where other rubber materials struggle.

Features

Heat resistance guide*: 335°C

Standard hardness (Duro A): 76

Compression set at high temperatures is small and it offers stable sealing performance over a long period of time.

*The guide for heat resistance differs according to various conditions.

Applications

Sealing of heat treatment units for manufacturing semiconductors and LCD concerning which heat resistance is particularly necessary (annealing furnaces, LPCVD units, etc)

Sealing of units, piping and valves used in various industrial fields

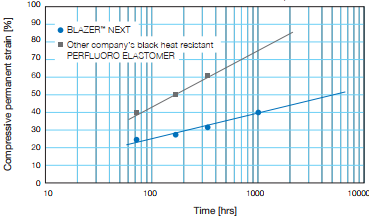

Compression set test results

Inspected by Nichias

Test conditions

- Measurement tool: see the figure above

- Test material: O-ring (AS568-214: φ3.53 mm × ID 25.0 mm)

- Heating temperature: 300°C

- Compression rate: 25% (when heated)

BLAZER NEXT’s compression set at high temperatures is less than that of a general product (FFKM), and it delivers stable sealing performance over the long term.

- TOMBO is a registered trademark or trademark of NICHIAS Corporation.

- Name of products with "®" are registered trademarks of NICHIAS Corporation.

- Name of products with "™" are trademarks of NICHIAS Corporation.

TOMBO™ No. 2675-S2 BLAZER™ O-ring-S2 (FFKM)

TOMBO™ No. 2675-S2

BLAZER™ O-ring - S2

BLAZER S2 is a perfluoroelastomer (FFKM) that shows stable sealing performance in environments with high-temperature steam and nucleophilic agents. It is a product with significantly improved steam resistance, rapid decompression properties, and crushing properties thanks to Nichias’ newly developed, original cross-linking agent and its proprietary mixing technologies.

Features

Heat resistance guide: 320°C

It is perfect for sealing against a wide range of chemical solutions that were difficult to use with conventional FFKM and FKM such as hot water, steam, amines, esters, ethers, ketonic acids, bases, hydrocarbons, and chlorinated solvents.

It is also suitable for use in environments that undergo rapid decompression.

A material that is not susceptible to compression failure at high temperatures.

Applications

Sealing such as for valves, pumps, turbo equipment, coating machines, centrifuges, mixers, analysis equipment, and reactors

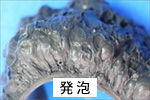

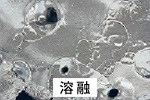

Steam resistance test results

Inspected by Nichias

| Specimen | BLAZER S2 | Nichias’ conventional product | General product (FFKM) | ||

|---|---|---|---|---|---|

| 320°C | 72h | Before test |

|

|

|

| After test |

|

Foam formation |

Melt |

||

In a high-temperature steam environment, the general product (FFKM) melts due to hydrolysis, but BLAZER S2 does not experience hydrolysis.

- TOMBO is a registered trademark or trademark of NICHIAS Corporation.

- Name of products with "®" are registered trademarks of NICHIAS Corporation.

- Name of products with "™" are trademarks of NICHIAS Corporation.

TOMBO™ No. 2675-A BLAZER™ O-ring-A (FFKM)

TOMBO™ No. 2675-A

BLAZER™ O-ring - A

BLAZER A is a perfluoroelastomer (FFKM) that has excellent chemical resistance and demonstrates resistance against polar solvents such as amines and chemicals such as organic acids that cannot be used with other fluoroelastomers. It suffers little metal elution and is suitable for applications that require both chemical resistance and purity.

Features

Heat resistance guide*: 210°C

Standard hardness (Duro A): 75

It has excellent chemical resistance and can be used for almost all chemical solutions. (Excluding fluorine-based solvents)

There is almost no elution of the metal from chemical solutions.

*The guide for heat resistance differs according to various conditions.

Applications

Sealing for cleaning equipment, coaters and developers (coating and developing equipment), wet etching equipment, and filters

- TOMBO is a registered trademark or trademark of NICHIAS Corporation.

- Name of products with "®" are registered trademarks of NICHIAS Corporation.

- Name of products with "™" are trademarks of NICHIAS Corporation.

TOMBO™ No. 2670-PFW Rubber O-ring Perfluoro PFW (FFKM)

TOMBO™ No. 2670-PFW

Rubber O-ring Perfluoro PFW

Rubber O-ring Perfluoro PFW is a perfluoroelastomer (FFKM) that has excellent plasma resistance and is used in dry etching equipment to manufacture semiconductors.

Features

Heat resistance guide*: 200°C

Standard hardness (Duro A): 70

It experiences little weight reduction when exposed to plasma and has excellent plasma resistance.

*The guide for heat resistance differs according to various conditions.

Applications

Sealing for plasma etching equipment, plasma CVD equipment, etc.

- TOMBO is a registered trademark or trademark of NICHIAS Corporation.

- Name of products with "®" are registered trademarks of NICHIAS Corporation.

- Name of products with "™" are trademarks of NICHIAS Corporation.

TOMBO™ No. 2675-FC BLAZER™ O-ring-FC (Special FKM)

TOMBO™ No. 2675-FC

Blazer O-ring-FC

BLAZER O-ring-FC (BFC) and BLAZER O-ring-FE (BFE) are made of special fluoroelastomers (special FKM) that are plasma resistant and inexpensive. Thanks to Nichias’ blending technologies, the plasma reduces the weight of the rubber and reduces the occurrence of cracks, and at the same time, it is significantly less expensive than perfluoroelastomer (FFKM).

Features

Heat resistance guide*: 200°C

Standard hardness (Duro A): 60

It is a material that is not susceptible to suffering a reduction in weight or cracks due to plasma exposure.

As it has excellent non-stickiness, it can also be used with movable parts without any problems.

It has a low metal content, thereby reducing any particle-related problems.

Applications

Can be used in semiconductor & LCD manufacturing equipment, the sealed parts that are exposed to the plasma environment

Parts that have problems in terms of lifespan and particles with FKM.

Parts for which the cost and performance are too great with FFKM.

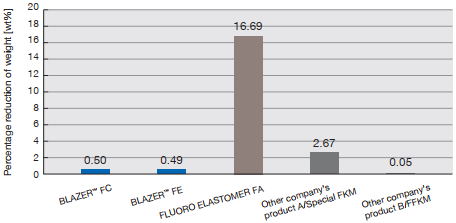

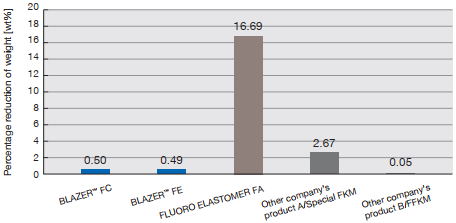

Plasma resistance (weight reduction rate)

Assessment conditions

Equipment: surface wave plasma etching equipment

Test sample shape: AS568B-214

Gas type: O2 (2000 SCCM) + CF4 (40 SCCM)

Pressure: 133 Pa

Output: 2000 W

Exposure duration: 2.0 hrs

Elongation rate: 5%

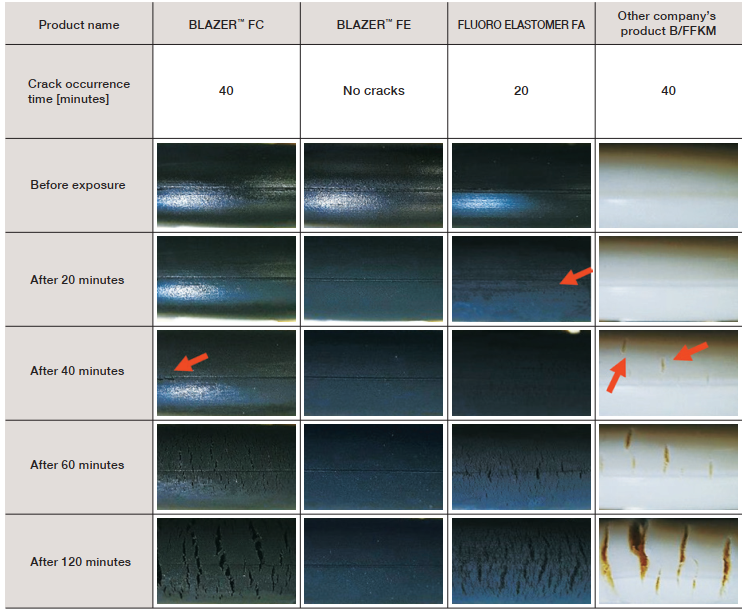

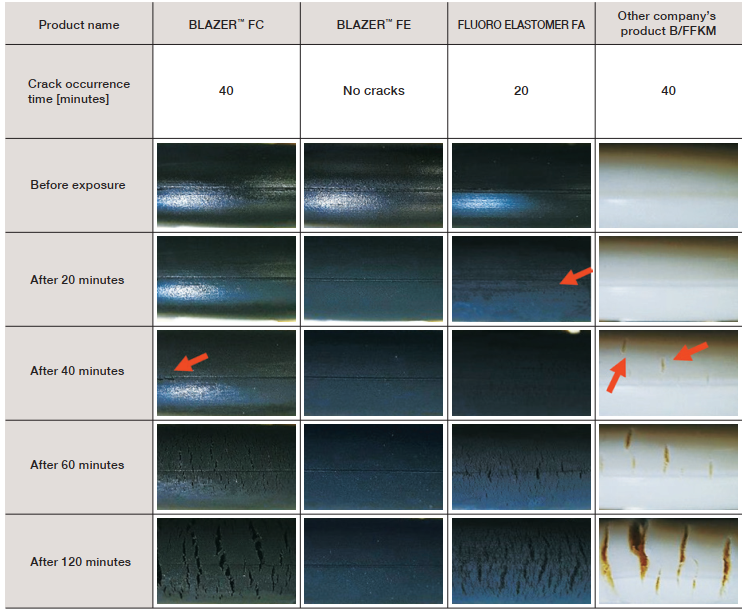

Plasma resistance (crack resistance)

Assessment conditions

Equipment: surface wave plasma etching equipment

Test sample shape: AS568B-214

Gas type: O2 (2000 SCCM) + CF4 (40 SCCM)

Pressure: 133 Pa

Output: 2000 W

Exposure duration: 2.0 hrs

Elongation rate: 5%

Appearance observation: up to 20 minutes with 5-minute intervals and then up to 120 minutes with 10-minute intervals

- TOMBO is a registered trademark or trademark of NICHIAS Corporation.

- Name of products with "®" are registered trademarks of NICHIAS Corporation.

- Name of products with "™" are trademarks of NICHIAS Corporation.

TOMBO™ No. 2675-FE BLAZER™ O-ring-FE (Special FKM)

TOMBO™ No. 2675-FE

Blazer O-ring-FE

BLAZER O-ring-FC (BFC) and BLAZER O-ring-FE (BFE) are made of special fluoroelastomers (special FKM) that are plasma resistant and inexpensive. Thanks to Nichias’ blending technologies, the plasma reduces the weight of the rubber and reduces the occurrence of cracks, and at the same time, it is significantly less expensive than perfluoroelastomer (FFKM).

Features

Heat resistance guide*: 200°C

Standard hardness (Duro A): 60

It is a material that is not susceptible to suffering a reduction in weight or cracks due to plasma exposure.

As it has excellent non-stickiness, it can also be used with movable parts without any problems.

It has a low metal content, thereby reducing any particle-related problems.

Applications

Can be used in semiconductor & LCD manufacturing equipment, the sealed parts that are exposed to the plasma environment (Sealing of plasma etching units)

Parts that have problems in terms of lifespan and particles with FKM.

Parts for which the cost and performance are too great with FFKM.

Plasma resistance (weight reduction rate)

Assessment conditions

Equipment: surface wave plasma etching equipment

Test sample shape: AS568B-214

Gas type: O2 (2000 SCCM) + CF4 (40 SCCM)

Pressure: 133 Pa

Output: 2000 W

Exposure duration: 2.0 hrs

Elongation rate: 5%

Plasma resistance (crack resistance)

Assessment conditions

Equipment: surface wave plasma etching equipment

Test sample shape: AS568B-214

Gas type: O2 (2000 SCCM) + CF4 (40 SCCM)

Pressure: 133 Pa

Output: 2000 W

Exposure duration: 2.0 hrs

Elongation rate: 5%

Appearance observation: up to 20 minutes with 5-minute intervals and then up to 120 minutes with 10-minute intervals

- TOMBO is a registered trademark or trademark of NICHIAS Corporation.

- Name of products with "®" are registered trademarks of NICHIAS Corporation.

- Name of products with "™" are trademarks of NICHIAS Corporation.

TOMBO™ No. 2670-FA-F Rubber O-ring Fluoro-Plus (Special FKM)

TOMBO™ No. 2670-FA-F

Rubber O-ring Fluoro-Plus

Fluoro-Plus is a special fluoroelastomer (Special FKM) that maintains the chemical resistance and heat resistance of a regular fluoroelastomer but has significantly improved wear resistance and non-stickiness.

Fluoro-Plus is different from outer membrane coatings and is a product that undergoes treatment by way of a surface improvement method. As a result, it maintains its attributes over the long term and it experiences no peeling of the surface layer.

Features

Heat resistance guide*: 200°C

Standard hardness (Duro A): 70

It Its friction coefficient is about 1/2 of a standard fluoro elastomer.

Its adhesion with metal is about 1/5 of a standard fluoro elastomer.

It undergoes surface modifying processing and so there is no peeling of the surface layer.

Applications

Sealing of parts that continuously slide or move along a surface, parts that open and close repeatedly (sealing of various control valves), and parts that adhere strongly to metal and are difficult to maintain

Precautions for use

Fluoro-Plus is less adaptable to mating surfaces than Fluoroelastomer FA, so do not use it for applications that require a high vacuum seal.

Non-adhesive

Inspected by Nichias

Test method

Test sample: O-ring (JIS P 26)

Compression rate: 25%

Flange material: aluminum

Heating conditions: 200°C × 22 hrs

- TOMBO is a registered trademark or trademark of NICHIAS Corporation.

- Name of products with "®" are registered trademarks of NICHIAS Corporation.

- Name of products with "™" are trademarks of NICHIAS Corporation.

TOMBO™ No. 2670-FB Rubber O-ring Fluoroelastomer FB (FKM)

TOMBO™ No. 2670-FB

Rubber O-ring Fluoroelastomer FB

Fluoroelastomer FB is a ternary fluoroelastomer (FKM) with improved chemical resistance due to Nichias’ proprietary compounding technologies. It has excellent resistance against high-temperature acids and steam for which a general-use fluoroelastomer cannot be used. There is very little metal elution and it has excellent purity. A high-performance fluoroelastomer that is excellent value for money.

Features

Heat resistance guide*: 200°C

Standard hardness (Duro A): 70

General-use fluoro elastomer can be used for quickly degrading, high-temperature inorganic acids, steam, and sodium hydroxide.

There is almost no elution of the metal from chemical solutions.

Applications

Cleaning equipment, wet etching equipment, filters, etc

Eluted metal measurement results

Inspected by Nichias

As fluoroelastomer FB is not a compound that contains metal, it experiences a lot less metal ion elution than that of fluoroelastomer FA.

Test conditions

Pre-cleaning

After cleaning with 5% hydrofluoric acid, it is cleaned with ultrapure water.

Elution

Test specimen: O-ring P16 (thickness Φ2.4 × inside diameter Φ15.8)

Chemical solution: 50% hydrofluoric acid 300 g

Temperature × time: 24°C × 72 hours (3 days)

Analysis method

ICP-MS

- TOMBO is a registered trademark or trademark of NICHIAS Corporation.

- Name of products with "®" are registered trademarks of NICHIAS Corporation.

- Name of products with "™" are trademarks of NICHIAS Corporation.

Giỏ hàng

Giỏ hàng