Features

Heat resistance guide*: 200°C

Standard hardness (Duro A): 60

It is a material that is not susceptible to suffering a reduction in weight or cracks due to plasma exposure.

As it has excellent non-stickiness, it can also be used with movable parts without any problems.

It has a low metal content, thereby reducing any particle-related problems.

Applications

Can be used in semiconductor & LCD manufacturing equipment, the sealed parts that are exposed to the plasma environment (Sealing of plasma etching units)

Parts that have problems in terms of lifespan and particles with FKM.

Parts for which the cost and performance are too great with FFKM.

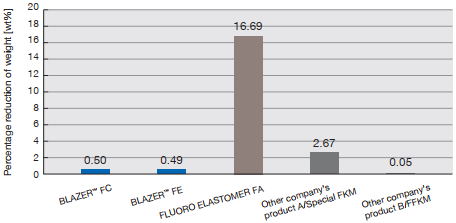

Plasma resistance (weight reduction rate)

Assessment conditions

Equipment: surface wave plasma etching equipment

Test sample shape: AS568B-214

Gas type: O2 (2000 SCCM) + CF4 (40 SCCM)

Pressure: 133 Pa

Output: 2000 W

Exposure duration: 2.0 hrs

Elongation rate: 5%

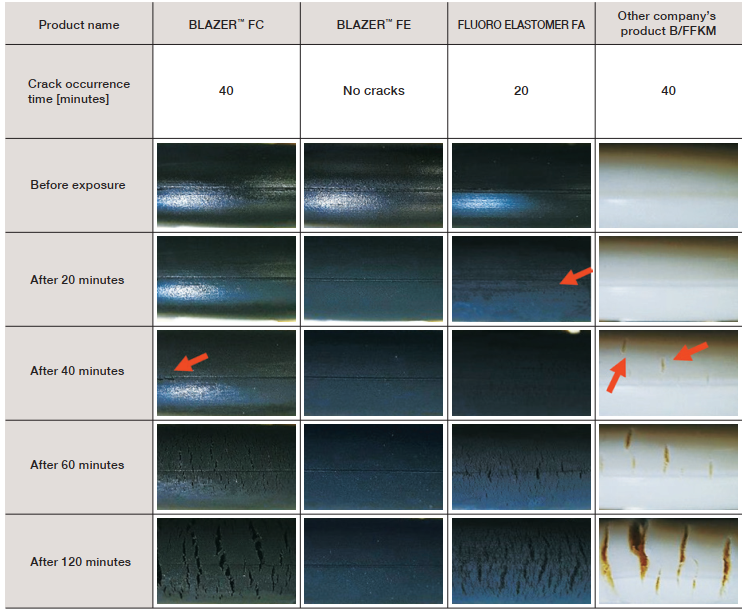

Plasma resistance (crack resistance)

Assessment conditions

Equipment: surface wave plasma etching equipment

Test sample shape: AS568B-214

Gas type: O2 (2000 SCCM) + CF4 (40 SCCM)

Pressure: 133 Pa

Output: 2000 W

Exposure duration: 2.0 hrs

Elongation rate: 5%

Appearance observation: up to 20 minutes with 5-minute intervals and then up to 120 minutes with 10-minute intervals

You addred [ ] to cart

You addred [ ] to cart