The race is on among automakers to create vehicles that offer continually higher performance. Today’s society, however, also demands close attention to making cars safer, more comfortable and more environmentally friendly. Progress is unstoppable. NICHIAS’ automotive parts business stemmed originally from its sealing materials operations. NICHIAS’ thermal insulation products are now used in engine parts, while damping materials prevent the screeching of brakes. New products are also on the horizon as the Company drives forward in pursuit of new fields.

NICHIAS' presence in the automotive industry has its roots in sealing materials. NICHIAS products have been employed in a variety of automotive components, the most notable being engine cylinders, which are exposed to the harshest conditions, exhaust manifolds and other engine-related parts. The purpose of sealing materials is self-evident. But manufacturing sealing materials requires the skill to select and develop the most appropriate materials and processing technologies according to location and service condition of each part. That is where NICHIAS comes in, with technical know-how, R&D capabilities and technological prowess nurtured over many years in this business.

The automotive industry has evolved by rising to the challenges of achieving low emissions, while improving fuel efficiency, safety, perfor- mance, comfort and affordability. For NICHIAS, these challenges present an ideal opportunity for using the Company’s core and original technologies. NICHIAS products are infiltrating new fields. In addition to sealing materials that prevent fluid leakage, NICHIAS is also developing heatproof materials, soundproof materials and damping materials that control vibration.

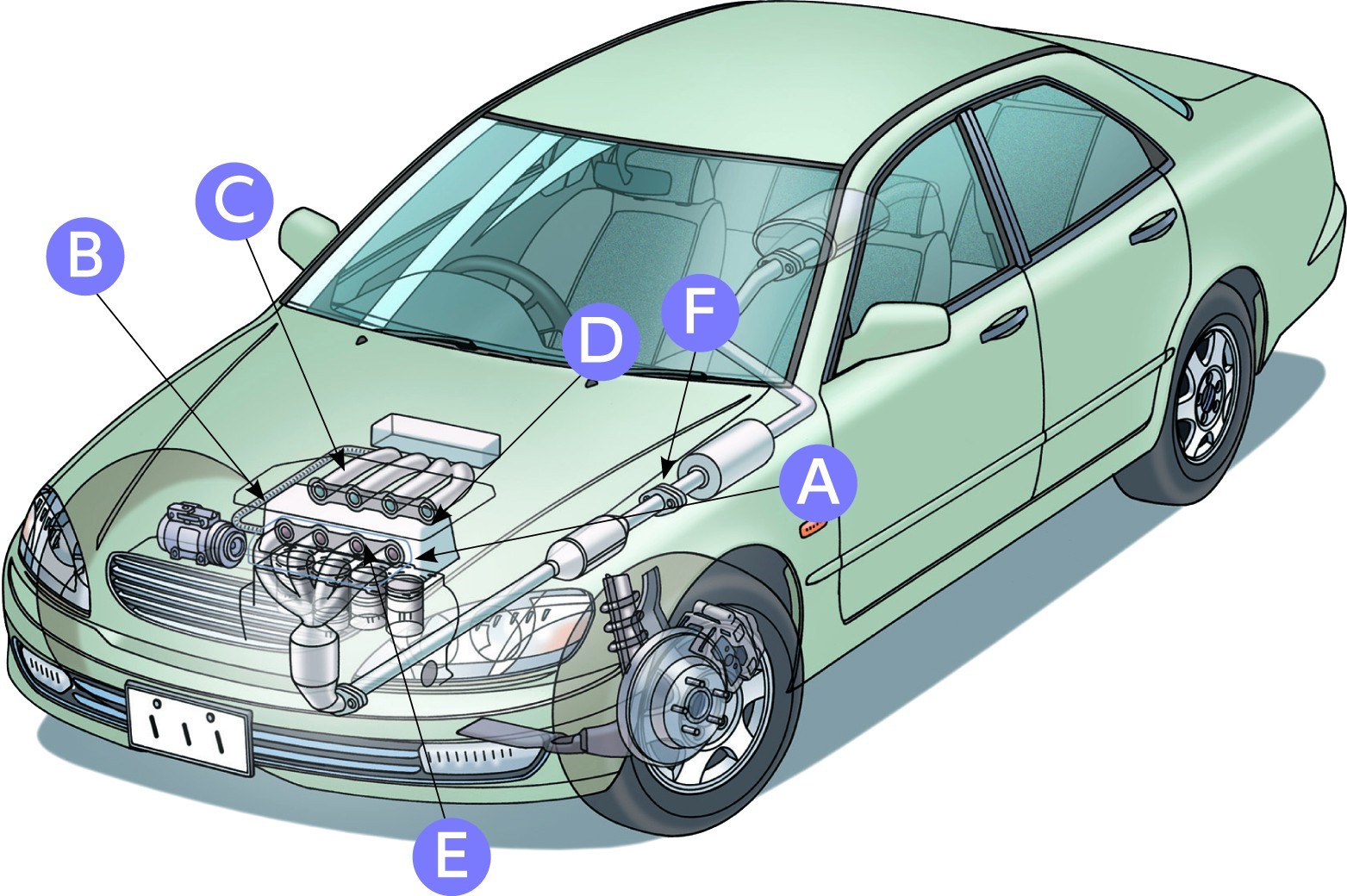

Automobiles Interactive Part 1

View our interactive drawing to see which NICHIAS products are used in the Automobile Industry.

| (A) Cylinder head gasket |  |

1600 METAKOTE™ This metal gasket is sandwiched between the cylinder head, which is the heart of the engine, and the engine block in order to seal off combustion gas, coolant, and lubrication oil. The gasket material is stainless steel sheet coated with high-heat-resistant rubber. It contains no environmentally hazardous substances and has excellent sealing performance and endurance |

| (B) Tube-shaped Insulators |  |

8700 N-Flex Tube, 8710-H N-Flex Tube HI Heat insulation tubes with excellent elasticity and flexibility. Ideal for covering cables and rubber hoses in the engine compartment to protect them from heat damage. they can be combined with heat insulation paper, aluminium foil, glass cloth etc., according to the application and can be used under a wide range of conditions. |

| (C) Ultra-lightweight Sound Insulation Cover |  |

AIRTONE™ Sound insulating cover featuring a lightweight design and excellent acoustic performance using unique nonwoven fabric sheathing. This cover is produced by laminating and casting a sound-absorbing PET felt layer to a specially treated nonwoven fabric with outstanding sound-insulating properties. |

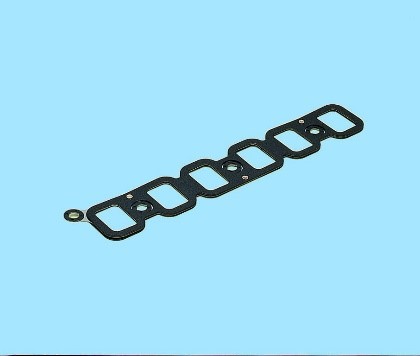

| (D) Intake Manifoled Gasket |  |

1608 METAFOAM™ Vibration Floating Gasket This gasket is used at the air intake of an engine, providing not only a sealing function but also insulation against engine vibration. The gasket material is metal plate coated with foam rubber. |

| (E) Exhaust Manifoled Gasket |  |

1850E Metal Gasket An engine exhaust gasket that provides excellent sealing performance for high-temperature combustion gas. It is structured with layers of stainless steel sheets. |

| (F) Exhaust Pipe Gasket |  |

1824 CR VORTEX™ A spiral wound gasket for exhaust pipes, made with alternating layers of thin stainless steel sheet and soft paper. It's excellent heat resistance and conformity prevents exhaust gas from leaking. |

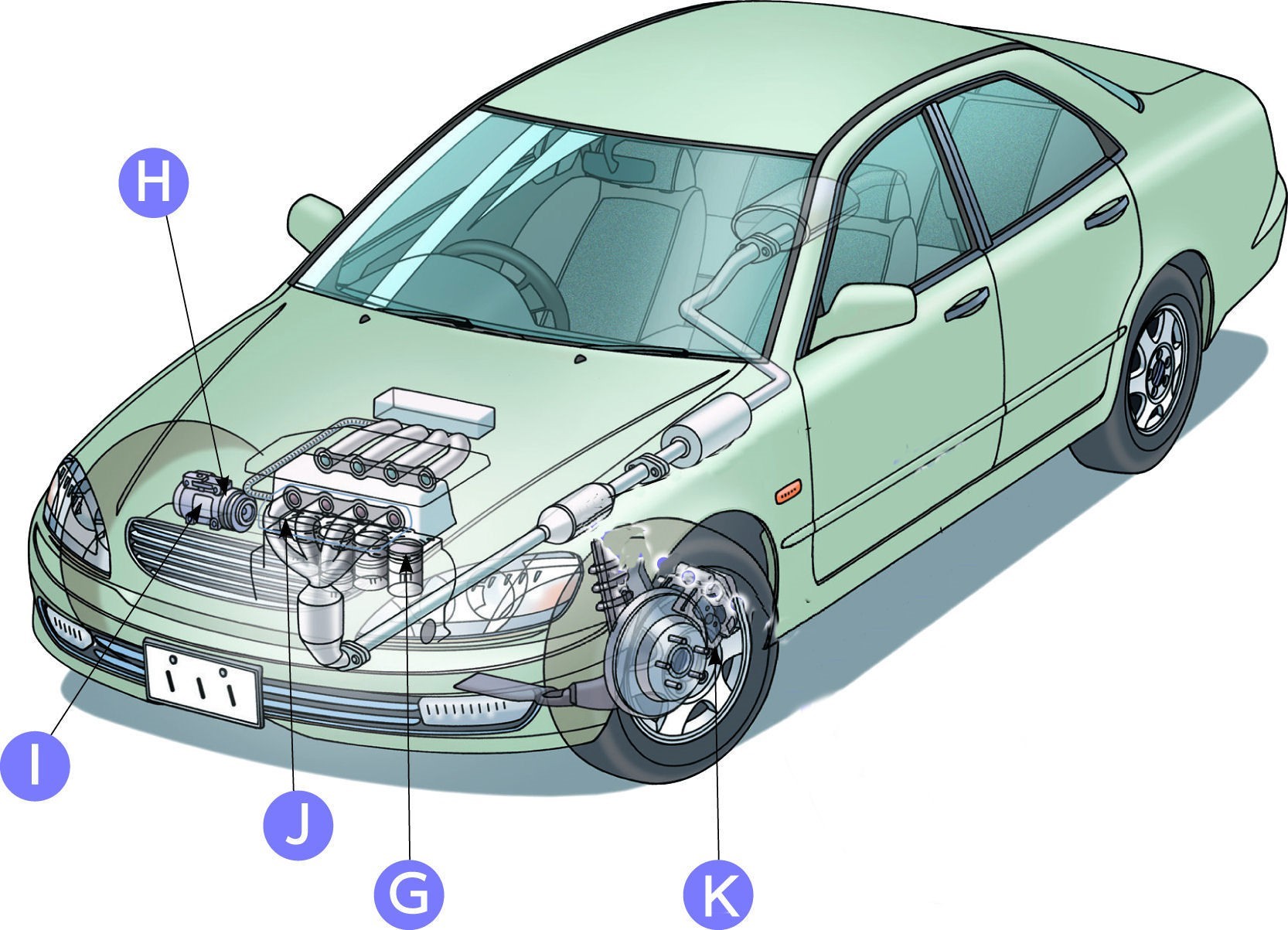

Automobiles Interactive Part 2

View our interactive drawing to see which NICHIAS products are used in the Automobile Industry.

| (A) Water Jacket Spacer |  |

Water Jacket Spacer This product is inserted into the water jacket of an engine. It controls this flow of the cylinder wall and reduces friction between the piston and the cylinder. The spacer is made of resin which improves fuel consumption. |

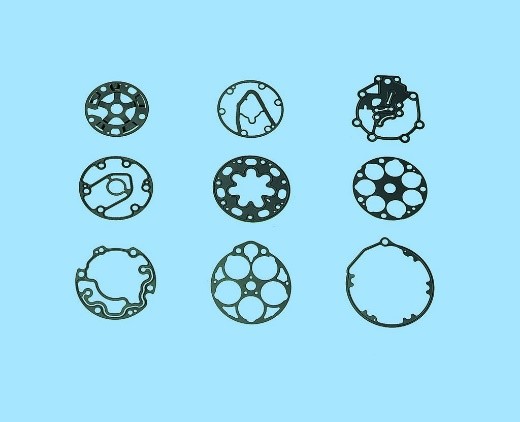

| (B) Gasket For Compressor |  |

1600 METAKOTE™ High performance gasket with excellent resistance to cooling medium and refrigerator oil, used in compressors for air conditioners. The gasket material is metal sheet coated with specially formulated NBR. |

| (C) Sliding Materials |  |

9550 EXCELIDE™ These sliding parts, made of multifunctional resin are used in equipment such as compressors, ATs and ABSs. Because of their high heat resistance and superior friction and wear resistance and properties, they are mainly used in parts (such as between a piston and cylinder) where both sliding and seal performance is required. |

| (D) Heat Insulator |  |

6600 INSULCOVER™ A metal cover that insulates against heat from the exhaust manifold. the combination of high-performance heat insulation materials and heat-resistant damping materials makes it extremely effective against noise and vibration. |

| (E) Brake Shims Material |  |

1612 METAPLUS™ Multi-Layer Shim An anti-squeal brake shim attached to the pad of a disc brake. The shim is made of laminated layers of rubber, metal and special adhesive to deliver an excellent vibration damping effect, along with high heat resistance and compression resistance properties. |

Giỏ hàng

Giỏ hàng