The demanding process conditions in Power Plants (including high temperatures and pressures) is an ideal environment for NICHIAS product technologies to be deployed.

Various NICHIAS thermal insulation and protection technologies are deployed from metallic heat insulation with Lead, to Wall penetration part sealing materials, to specialist gaskets proven in use in the NUCLEAR Industry, to re-usable flexible heat insulation materials, calcium silicate thermal insulation materials and high damping rubber/metal composite sheets used in THERMAL POWER Plants.

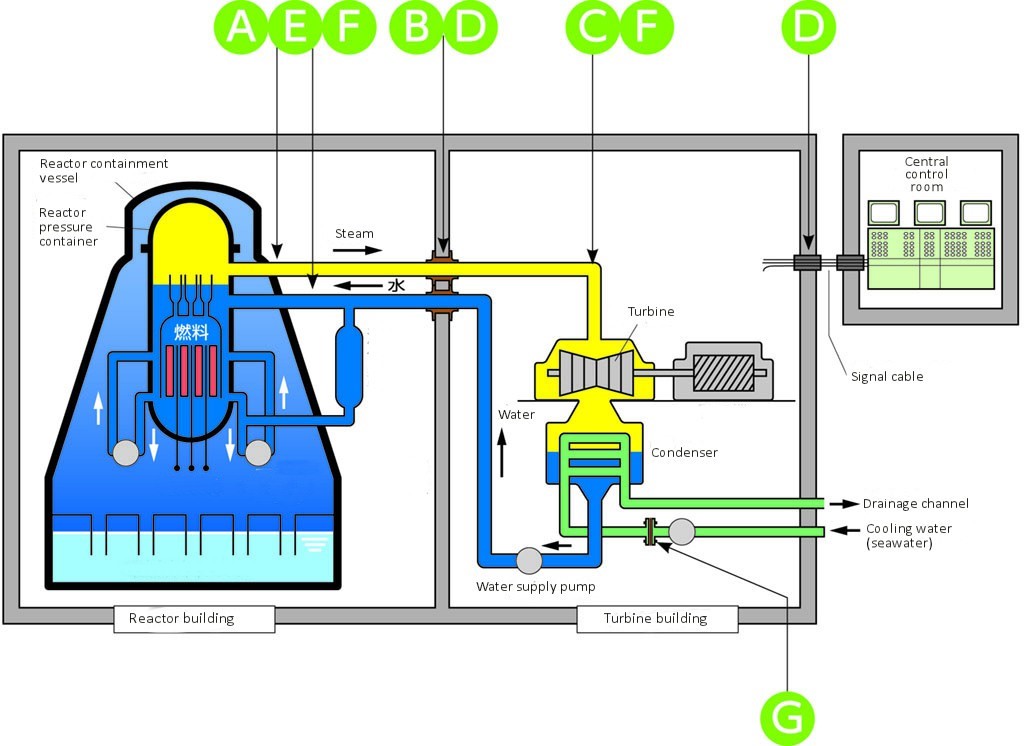

Nuclear Power Plants

The extreme process conditions in Nuclear Power Plants has demanded the use of NICHIAS product technologies.

NICHIAS supplies Wall penetration part sealing materials which are used on walls and floors through which piping and cabling pass - as it has excellent air tightness, water tightnesss and radiation resistance, to metallic heat insulation with lead which is used as a heat insulation material for applications requiring radiation shielding performance as in equipment and piping inside the reactor containment vessel (lead sheets are combined with the metal heat insulation materials), to metallic heat insulation materials used for the pressure container of nuclear reactors in re-circulation equipment, to specialist bellows (flexible expansion joints made of special rubber materials) which are used to seal the clearance between the pipes penetrating buildings, walls and floors and the pipe holes in a nuclear power plant, to specialist gaskets proven in use in the nuclear industry, to re-usable flexible heat insulation materials for the insulation of piping, valves, flanges, etc where the insulation material needs to be able to be removed during plant inspection and maintenance.

| (A) Heat Insulation Material for Nuclear Power Plants |  |

Metallic Heat Insulation Metallic hot insulation material used for the pressure container of nuclear reactors, in recirculation equipment, and every kind of equipment and piping. There is no risk of corrosion since it is made of thin stainless steel sheet. The mechanical strength is excellent and it can be attached and detached quickly to reduce exposure when working. |

| (B) Building Penetration Part Sealing Material |  |

9999-NA NA Bellow-Q™ A flexible expansion joint made of special rubber material, used to seal the clearance between the pipes penetrating buildings, walls and floors and pipe holes in a nuclear power plant. this joint has excellent nuclear radiation resistance, heat resistance and flexibility, and is used as sealing material against radiation contamination air, steam generated in an accident, smoke and water generated in a fire etc. |

| (C) Heat Insulation Material Made of Rock Wool |  |

MG FELT™ Heat insulation material made of rock wool used for piping and equipment. It is made by melting and fiberizing a mixture of slag and highly heat-resistant ore composed mostly of limestone and silicic acid. adding a binder to it, and then forming it into a board-like material. |

| (D) Wall Penetration Part Sealing Material |  |

PENESEAL™ CT-18 Sealing material used on walls and floors through which piping and cabling pass. It has excellent air tightness, water tightness and radiation resistance. |

| (E) Heat Insulation Material for Nuclear Power Plant Equipment |  |

Metallic Heat Insulation with Lead Used as heat insulation material for applications requiring radiation shielding performance as in equipment and piping inside the reactor containment vessel. Lead sheets are combined with the metal heat insulation material. |

| (F) Reusable Flexible Heat Insulation Material |  |

ENETHERMO™ K Reusable heat insulation material for the insulation of piping, valves, flanges etc. It is suitable for areas where the insulation material must be removed during plant inspection. A waterproof type is also available for outdoor use. |

| (G) Spiral Wound Gasket |  |

GRASEAL™ VORTEX™ Gasket A spiral wound gasket with expanded graphite tape filter, used for pressure vessels, heat exchangers, valves and other equipment in a nuclear power plant. Suitable for the high-temperature and high-pressure conditions of the nuclear power plant; the amount of soluble chlorine, fluorine and sulfur is controlled to meet the requirements for use in nuclear power plants |

Thermal Power Plants

A variety of NICHIAS product solutions are deployed in a Thermal Power Plant.

NICHIAS supplies multiple thermal insulation materials ranging from rock wool used as thermal and acoustic insulation in ducts boilers and dust collectors, to calcium silicate thermal insulation materials used for various piping and ducts since it is easy to install and has high mechanical strength and water resistance to castable refractories used for protecting iron plates and refractory bricks in boilers from acidic gases and heat, to re-usable flexible heat insulation materials for the insulation of piping, valves, flanges, etc where the insulation material needs to be able to be removed during plant inspection and maintenance, to specialist gaskets used as sealing materials for piping flanges, valves and equipment both of high temperature and pressure duty but also low temperature and pressure duty, to high damping sheets (Metalamine™) which is an exterior pipe acoustic insulation sheet used on the smoke paths, airways, electric dust collectors, etc of a thermal power plant to reduce noise and vibration generated.

| (A) High Damping Sheet |  |

METALAMINE™ A pipe acoustic insulation exterior sheet used on the smoke paths, airways, electric dust collectors etc. of thermal power plant. It has excellent acoustic insulation effects due to its multi-layer structure of metal and rubber. It is easy to work with and durable as an exterior sheet for piping, reducing the noise and vibration generated by smoke paths and airways. |

| (B) Spiral Wound Gasket |  |

GRASEAL™ VORTEX™ Gasket A spiral wound gasket with expanded graphite tape filter, used for pressure vessels, heat exchangers, valves and other equipment in a nuclear power plant. This gasket is suitable for high-temperature, high-pressure steam or fluid such as heavy oil and naphtha as well as for low temperature fluid such as LNG. |

| (C) General-Purpose Joint Sheet |  |

CLINSIL™ Brown Non asbestos joint sheet used as sealing material for piping flanges, valves and equipment. it is used for gaskets to prevent leakage of low temperature, low pressure water, oil, other fluids and air. |

| (D) Castable Refactory |  |

TOMBO™ Fire-Resistant Caster Castable refractory for protecting iron plates and refractory bricks in boilers from acid gases and heat. in addition to its excellent heat resistance, it is easy to apply to various forms of furnace walls using sprays or trowels |

| (E) Ceramic Fiber |  |

FINEFLEX™ Blanket Ceramic fiber material used for general high-temperature heat insulation and as a heat insulation material on the ceiling and walls of kilns. It si also used as heat insulation material on high-temperature exhaust ducts. |

| (F) Heat Insulation Material Made of Rockwool |  |

MG BOARD™ Heat insulation material made of rock wool used for thermal insulation, noise reduction in ducts and as backup material for ceramic fiber furnaces. It is also used for acoustic insulation and heat insulation of boilers, ducts, dust collectors etc. |

| (G) Non-Mettalic Flexible Expansion Joint |  |

NA BELLOW-Q™ A non-metallic expansion joint used to smoke airways in various piping and duct systems. This product absorbs the expansion and contraction movement of such as large-diameter duct piping caused by thermal expansion or vibration. |

| (H) Calcium Silicate Thermal Insulation Material |  |

KEICAL ACE SUPER SILICA™ Calcium silicate heat insulation material used for various piping and ducts. Since it is easy to install, and has high mechanical strength and water resistance, it is used as heat insulation material at high temperatures, up to a high heat resistance of 1000ºC |

| (I) Reusable Flexible Heat Insulation Material |  |

ENETHERMO™ Reusable heat insulation material with excellent heat insulating properties, used for valves, flanges, turbines, pumps, boilers etc. A waterproof type is also available for outdoor use. |

| (J) Degraded Insulation Resuscitation Method |  |

e'-AIM™ (eco-Advanced Insulation Method) A method of restoring thermal insulation performance by winding insulation material over the degraded insulation material without removing it. |

Giỏ hàng

Giỏ hàng